Hot stamping is indeed an exciting method of applying heat to transfer a distinctive design on various surfaces. Typically, this technique is more commonly attributed to stamping logos and cool-looking designs onto books, boxes, and at times leather. We love a little hot stamping at Shunho Creative because there is nothing like it to give your brand applications a competitive edge. In this guide, we will break down what you need to know about hot stamping and how it is truly a benefit for you and your products!

Hot stamping is a highly versatile method, which can be applied to a wide variety of substrates. Hot stamping will work with various types of materials which include, but are not limited to paper, cardboard, fabric, leather and even plastic. Depending upon the type of material you go for, the required temperature and pressure to achieve a clear image will vary. You can also utilize shiny & metallic inks in hot stamps, which enhances the individual design and makes them sparkle extra.

Now that you understand what hot stamping is all about, allow us to provide some useful tips that can improve your hot stamping projects! The most important one is to choose the suitable material for your project. For instance, certain materials, such as leather(Have to have a temperature greater than like that of paper which has lesser heat. So its very important to test the material first before hand when figuring out what works for your design.

Now, spend some time considering the design on which you are going to stamp. Hot stamping is most effective with simple flat designs that have only a few lines and shapes. Things like complicated designs that include a lot of tiny details may be difficult to stamp. At the same time, you should select the right color of ink that matches your project. Bright, shiny or metallic inks can give your designs an elegant and alluring look but tend to be more difficult to run.

That's why how you use that stamp is important as well. You must exert sufficient pressure for the ink to be transferred onto the substrate, but not so much that you damage or destroy your material. To get it right, the temperature of the stamp must be adequate. Finally, you allow the material to cool and carefully lift away the stamp after stamping. Reasons this is important will ensure that the design goes in place.

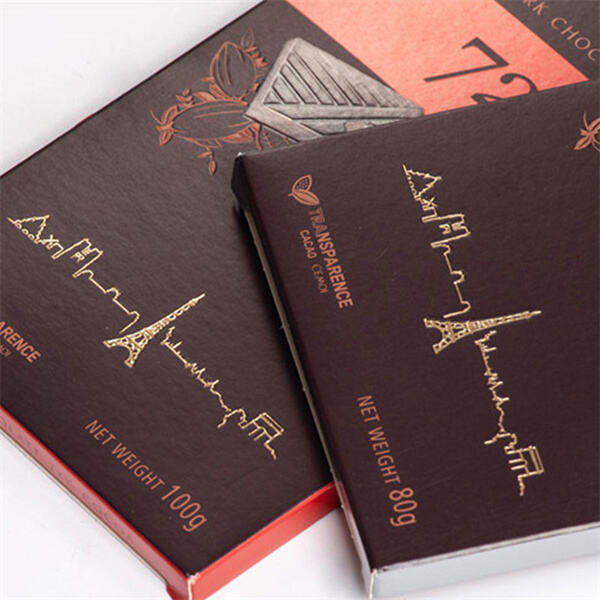

Hot stamping is a great technique to lend your items that professionally glazed appearance. This is a very practical and cost-friendly practice in order to customize the items you sell, as well as brand of your items. One of the embossing techniques is hot stamping, through which you are able to imprint logos, names, or anything else on your products. This might help your goods compete and be noticeable as compared against each other in the market.

Hot stamping is more widely used on a variety of materials. Since then it has become especially popular within the fashion industry and leather goods. You can hot stamp your own custom belts, wallets, or any other leather goods that you want to personalize; they look great! However, that fun does not end there! Additionally, paper products like business cards, invitations or packaging are commonly hot stamped as well. Hot stamping is so versatile that it can also be used with common materials such as plastic and fabric.

English, Spanish, stamping hot, Korean and other languages are supported.Provide complete solutions from raw the raw materials to the final product.

With FSC, stamping hot, FDA 21 CFR 176.170, (EU) No 10/2011, TUV OK COMPOST HOME, RECYCLABLE, ISO 9001/14001/45001, CNAS, PATENTS and other environmental protection certificates

The majority of customers come from the stamping hot 500 companies in the world

stamping hot paper production can reach 200 tonnes per year.